Flare Minimisation

Reducing Flaring. Enhancing Efficiency. Protecting the Environment.

At MHH Catalyst & Technologies, we specialize in flare minimisation strategies that help industries reduce emissions, recover valuable energy, and comply with environmental regulations. Our solutions are designed to cut operational costs while promoting sustainable growth.

Introduction

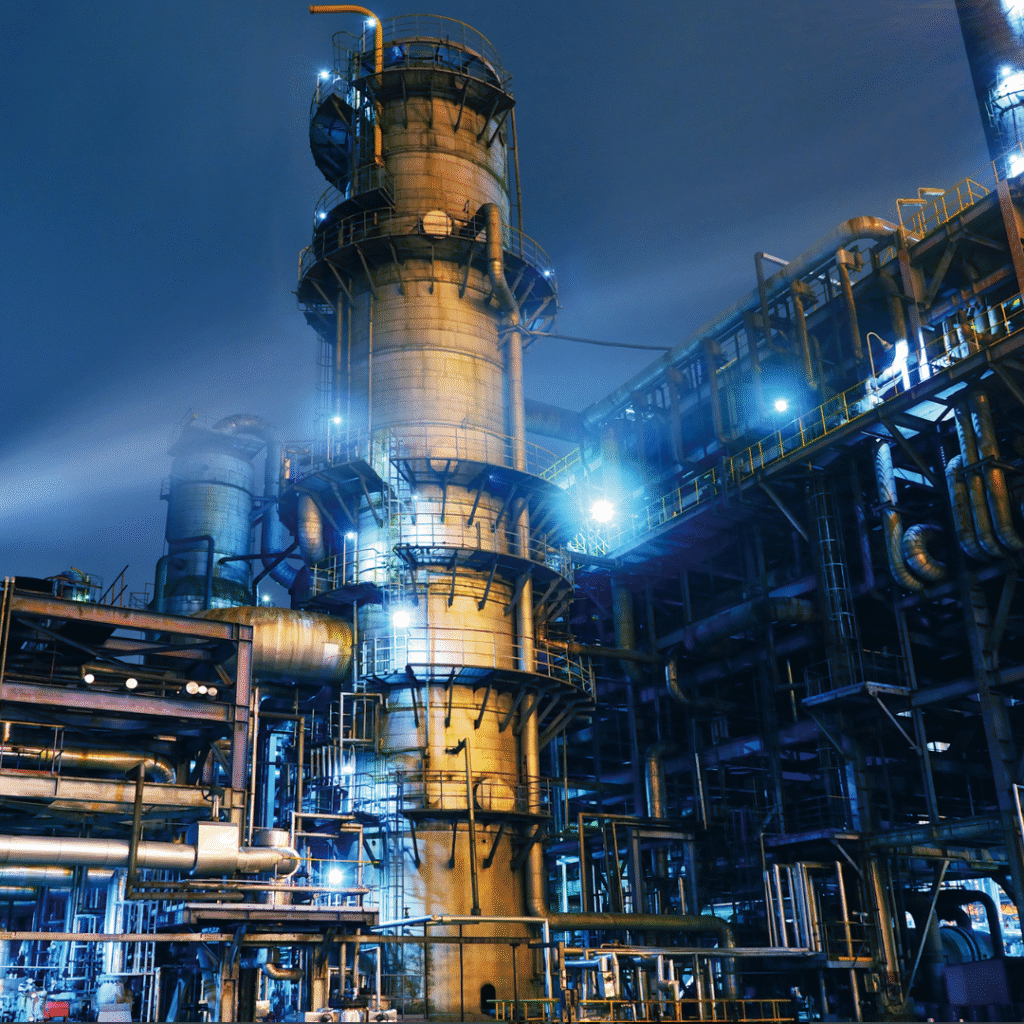

Flaring is one of the biggest environmental and operational challenges in the Oil & Gas and Petrochemical sectors. Beyond energy loss, excessive flaring contributes to greenhouse gas emissions, regulatory penalties, and reputational risks.

Through advanced process engineering and digital monitoring systems, MHH Catalyst & Technologies helps industries minimize routine and non-routine flaring. Our expertise ensures safer operations, reduced carbon footprint, and optimized asset performance.

Key Benefits of Flare Minimisation

Environmental Compliance

Stay aligned with international emission standards.

Energy Recovery

Capture and utilize gases that would otherwise be wasted.

Improved Safety

Minimise risk by controlling excess pressure in a safer way.

Cost Reduction

Lower fuel and operational expenses by reducing unnecessary flaring.

Sustainability

Demonstrate commitment to cleaner, greener operations.

Our Approach

We adopt a holistic methodology to deliver effective flare minimisation solutions:

Process Analysis

Assess current flaring activities and identify causes.

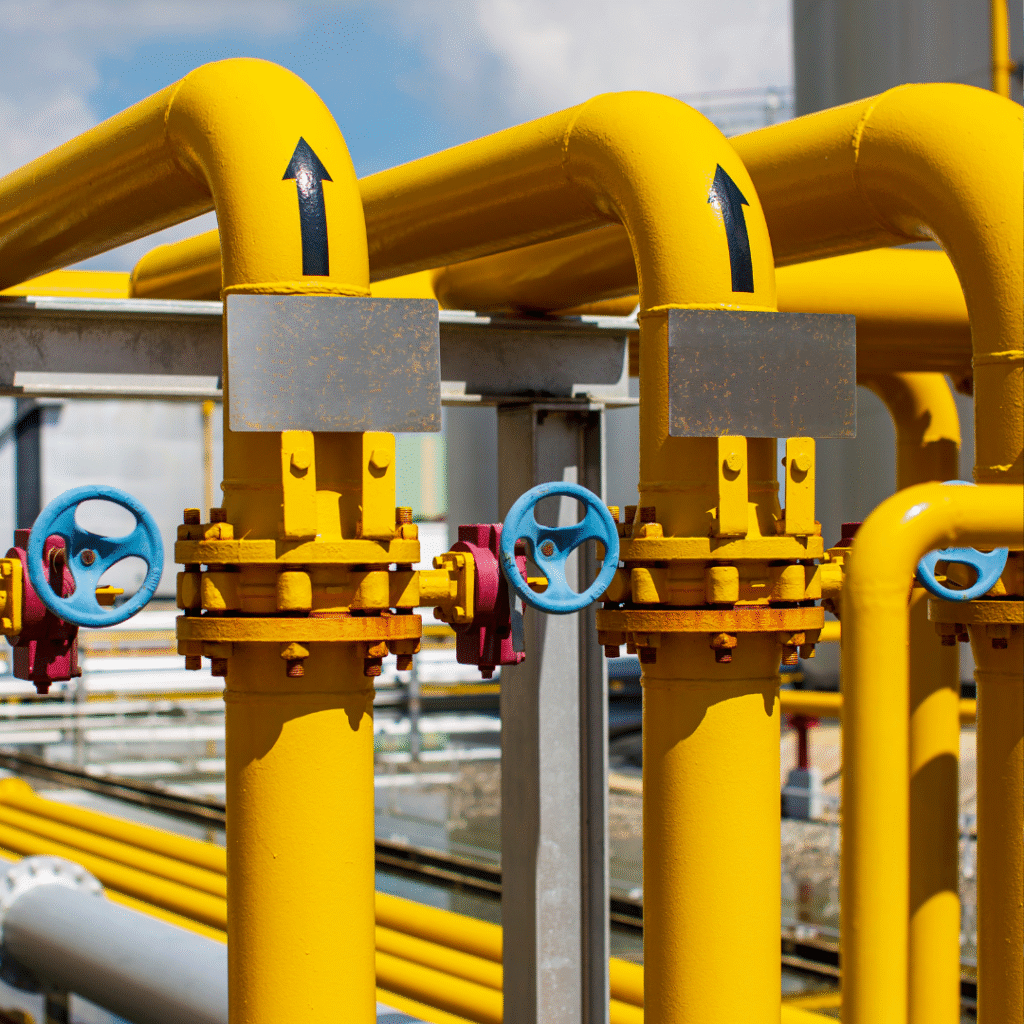

Technology Integration

Deploy flare gas recovery systems, compressors, and digital control tools.

Optimization & Monitoring

Enable real-time tracking of flaring levels with IoT & analytics.

Training & Compliance

Support teams in meeting international environmental and safety standards.

Continuous Improvement

Ensure long-term sustainability through upgrades and technical support.