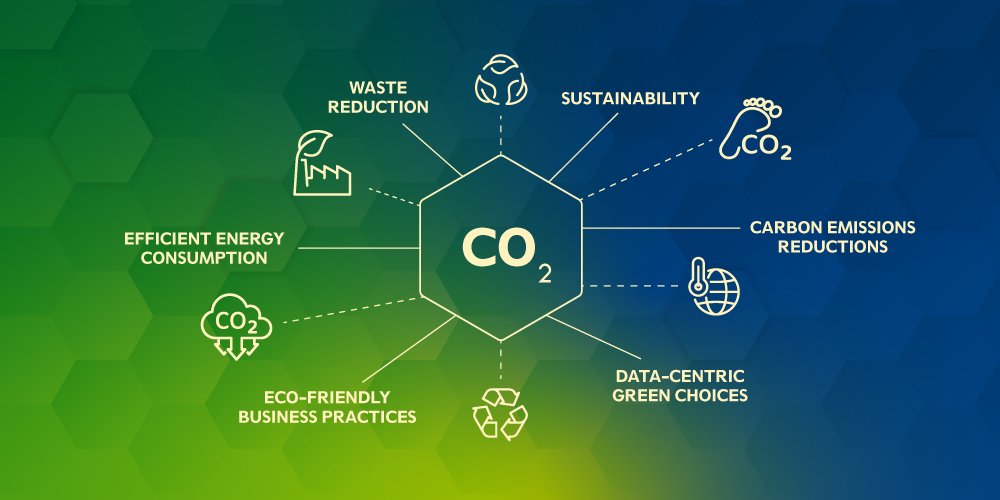

Carbon Management & Sustainability

Help your organization meet Net-Zero goals with practical, science-backed catalytic pathways and process innovation.

Carbon-Efficient Catalytic Cycles

Designing catalytic processes that minimize CO₂ emissions from the ground up is essential for decarbonizing the industrial value chain.

Key Features

Develop low-carbon catalytic routes that reduce CO₂ at the molecular level.

Use selective oxidation, reforming, or isomerization pathways to limit byproduct formation. Integrate carbon capture and utilization (CCU) within process design. Focus on maximizing product yield per carbon input, boosting atom economy.

Lower direct (Scope 1) and indirect (Scope 2) emissions.

Improved feedstock efficiency.

Stronger compliance with climate targets and green regulations

OPEX-Reducing Sustainability Models

Sustainability doesn’t have to cost more—it can actually reduce operational expenses.

Key Features

Retrofit legacy catalytic systems for energy and material efficiency. Integrate waste heat recovery, utility optimization, and resource recycling loops. Real-time KPI monitoring through digital dashboards. Extend catalyst lifecycle and minimize regeneration intervals.

Benefits

Lower utility bills and raw material losses. Increased asset uptime and reliability. Faster ROI on green investments.Our process optimization and energy integration strategies significantly cut down on electricity, steam, and cooling demands. By minimizing waste streams and improving material efficiency, we help reduce both operating expenses and raw material consumption—resulting in leaner, more cost-effective production cycles.

Green Fuel Transition Strategies

We provide comprehensive solutions to support your transition from traditional fossil-based operations to renewable and low-carbon fuel alternatives. Our expertise spans process redesign, feedstock integration, catalyst selection, and emissions reduction strategies — enabling a smooth, efficient, and economically viable shift toward sustainable energy production.

Key Features

We provide advanced catalytic conversion technologies for transforming biomass, bio-oils, and industrial or municipal waste into high-value synthetic and renewable fuels. Our processes are designed to upgrade a wide range of bio-feedstocks—such as pyrolysis oils, lignocellulosic residues, and used cooking oils—into refined fuel products that meet industry-grade drop-in standards. This includes renewable aviation fuels, green diesel, and other hydrocarbon-based fuels that are fully compatible with existing engine and distribution infrastructures.

Benefits

By integrating renewable feedstocks, alternative energy inputs, and efficient catalytic processes, our solutions help industries significantly lower their reliance on conventional fossil fuels. This not only reduces exposure to volatile oil and gas markets but also supports a long-term transition toward more sustainable and resilient operations. Our technologies and process strategies are designed to align with modern Environmental, Social, and Governance (ESG) benchmarks. Companies adopting these solutions demonstrate proactive environmental stewardship, which enhances brand value, builds trust with stakeholders, and strengthens their positioning in an increasingly sustainability-conscious marketplace.

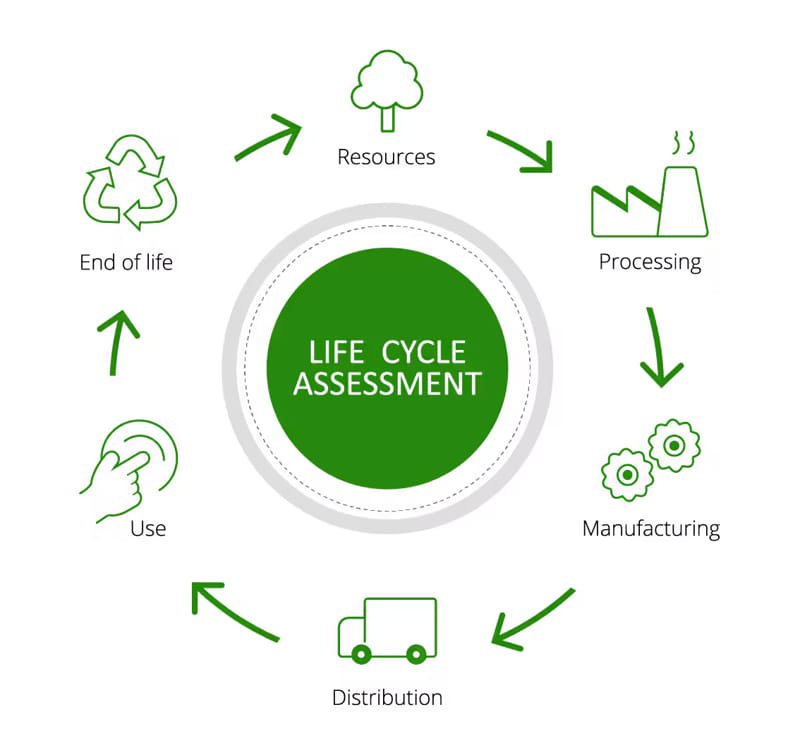

Lifecycle Assessments and Optimization

Gain full visibility into the environmental footprint of your operations—across every stage, from raw material sourcing to final product delivery. Our integrated approach combines data-driven assessments, real-time monitoring, and performance benchmarking to help you identify key impact areas. We then provide targeted solutions to reduce emissions, minimize waste, conserve energy, and align your processes with global sustainability standards. The result is a measurable improvement in environmental performance, operational efficiency, and corporate responsibility

- Conduct full Life Cycle Assessments (LCA) for chemicals, fuels, and processes.

- Map carbon intensity across process units, products, and supply chains.

- Use digital twins and modeling to evaluate future scenarios and risk factors.

- Provide customized recommendations to reduce overall environmental impact.

- Data-driven sustainability improvements.

- Improved product stewardship and audit readiness.

- Stronger alignment with circular economy principles.