Refinery & Petrochemical Process Optimization

Optimize your plant's performance, reduce OPEX, and meet environmental targets with cutting-edge catalytic and engineering solutions.

Refinery Integration

Feedstock Conditioning

Furnace Coil Catalysis

Flare and Energy

Performance Analytics

Refinery-Petrochemical Integration

Integrated refinery and petrochemical integration (RPI) operations are essential for generating large revenues as transportation and other fuel related sectors are going electric. Surplus crude oil availability in the global level in the coming years is forcing companies to divert towards RPI. Catalytic units play crucial role in improving product flexibility, reducing energy consumption, and maximizing profitability.

Details

Chemical and physical conditioning of various feedstocks (crude, naphtha, VGO, etc.) to meet processing specifications.

Decontamination and impurity removal using catalytic and adsorption-based techniques.

Tuning catalyst parameters and process conditions to stabilize product properties.

Troubleshooting off-spec issues related to sulfur content, octane number, olefin/paraffin ratios, etc

Benefits

Increased product diversity and margin.

Lower capital and operational expenditure

Enhanced long-term sustainability.

Feedstock Conditioning & Product On-Spec Optimization

Efficient processing starts with the careful conditioning of feedstock to ensure it meets precise input specifications—free of contaminants and optimized for reactivity. From there, every step of the process is designed to preserve material integrity, maximize yield, and maintain consistency.

Details

Chemical and physical conditioning of various feedstocks (crude, naphtha, VGO, etc.) to meet processing specifications.

Decontamination and impurity removal using catalytic and adsorption-based techniques.

Tuning catalyst parameters and process conditions to stabilize product properties.

Troubleshooting off-spec issues related to sulfur content, octane number, olefin/paraffin ratios, etc.

Benefits

1. Stable and consistent product quality.

2. Minimized reprocessing and rejects.

3. Improved downstream unit reliability.

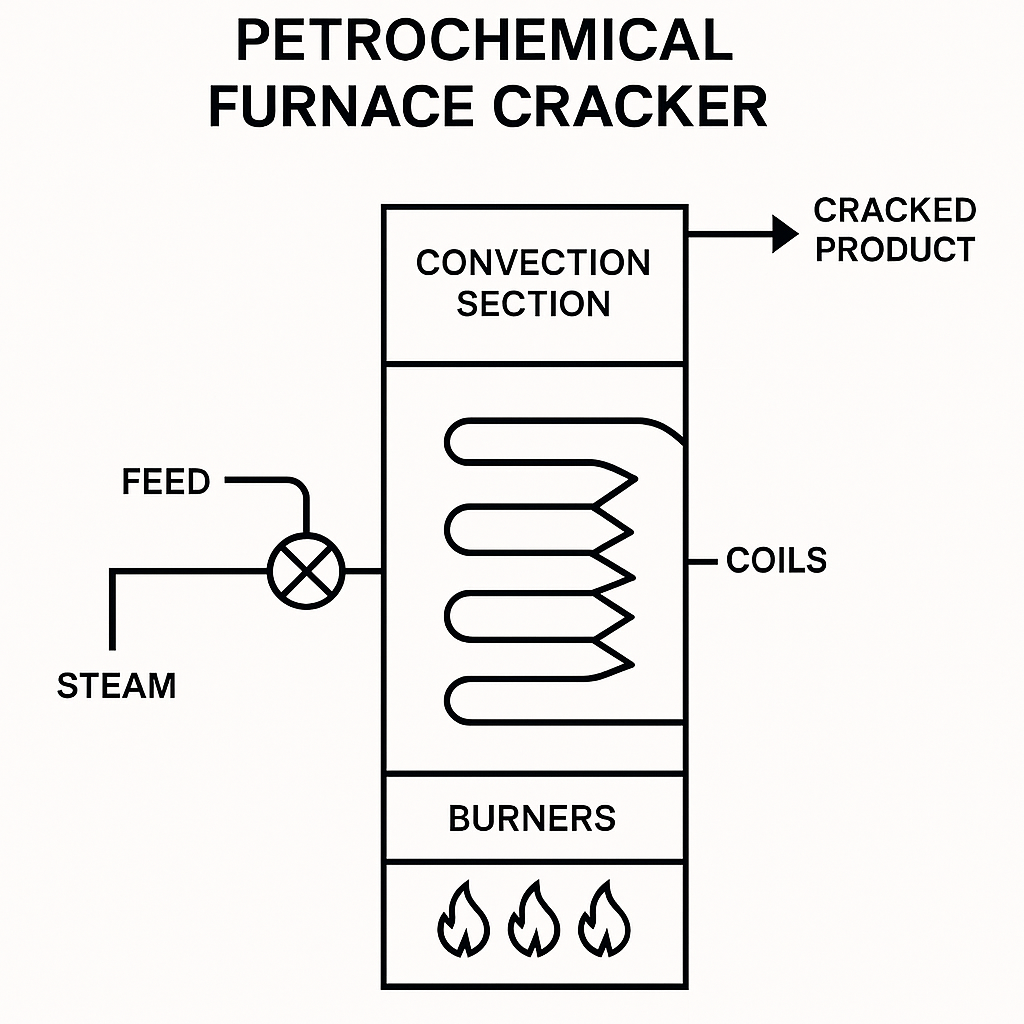

Furnace Coil Catalysis

Furnace performance is crucial in pyrolysis and cracking operations. We provide advanced catalytic coatings and materials for enhanced heat transfer and reduced fouling.

Details

Design and deployment of high-performance catalyst coatings on furnace coils. Enhanced resistance to coking and degradation under extreme thermal conditions. Integration with advanced metallurgy and flow optimization techniques.Real-time performance monitoring and lifecycle evaluation.

- Benefits

- Longer furnace run lengths.

- Reduced decoking frequency and maintenance.

- Improved selectivity and energy efficiency.

Performance Digitization & Analytics

Leverage digital technologies to monitor, optimize, and control plant operations in real-time.

Details

Implementation of sensor networks and smart analytics for live data capture. Development of custom KPIs and dashboards for performance tracking. AI/ML-based process optimization algorithms for predictive control. Integration of digital twins for scenario analysis and future-proofing.

Benefits

Enhanced decision-making with actionable insights.

Early detection of inefficiencies and anomalies. Continuous performance improvement and cost control.

Flare and Energy Loss Reduction

Flare minimization is not just about compliance—it’s about improving energy recovery and operational efficiency.

Details

Audit and analysis of flare system performance and design. Identification of leakages, pressure imbalances, and startup/shutdown inefficiencies. Installation of flare gas recovery systems and flare minimization controls. Integration with DCS and plant automation for predictive alerts.

Benefits

Lower GHG emissions and better ESG scores. Significant energy and cost savings. Compliance with environmental regulations (e.g., MARPOL, EPA).